RPM prioritizes and works to improve support for our associates’ mental, emotional and physical wellbeing. Environmental, health and safety (EHS) is overseen by RPM’s Vice President of EHS through our center-led approach. This involves close coordination and cooperation with our operating group EHS leaders and other EHS professionals at our operating companies monitoring associate health and safety.

Our Core EHS Fundamentals facilitate the prevention of and proactive response to safety incidents by requiring accountability at all RPM locations. We provide EHS guidance on best practices and reinforce shared responsibility for safety to all associates and leaders. Through our center-led EHS management program, we identify improvement opportunities and areas of focus both locally and on a consolidated, corporate-wide basis. We deliver center-led EHS leadership training programs, implement EHS policies and procedures specific to our facilities and establish goals to address areas for improvement. In the event of an incident, we require an incident investigation report with a full root-cause analysis to be submitted to senior EHS management and operating company presidents for each recordable safety incident.

To cultivate a proactive safety culture, we set high expectations and operational standards aligned with our Environmental, Health and Safety Policy. Six Core EHS Fundamentals help us uphold this culture:

- Safety Vision

- Engagement & Accountability

- Commitment to Professional Resources

- Measure & Report Safety Metrics

- Establish Safety Goals

- Continuous Improvement

HIGHLIGHT

Our unwavering commitment to robust safety protocols and a culture of accountability and awareness is evident through the milestone achievements of multiple RPM businesses in 2024. The team at our Rust-Oleum Canada facility achieved 16 years with no lost-time injuries. Similarly, our Viapol site in Candeias, Brazil, reached four years without a lost-time injury. The team at our Legend Brands site in Burlington, Washington, significantly reduced its total recordable incident rate (TRIR) by 86% year over year.

ADDITIONAL INFORMATION

Learn more about our key EHS metrics and performance on our Reports & Downloads page.

We embed safety into our culture through the deployment of regular center-led communications with plant and distribution center associates, as well as temporary workers. Through frequent and multifaceted methods of communication, compliance and safety topics remain at the forefront of our engagement with our global workforce to reinforce our safety commitments through education and action, and to comply with regulatory obligations.

A few of the ways we incorporate safety messages into our regular communications with employees include toolbox talks and EHS topic posters in multiple languages, quarterly EHS professional development webinars, monthly and annual EHS leadership forums and weekly and monthly EHS training programs at local and regional levels.

EHS highlights from FY25 include:

- 70 members of our EHS team and Operations leadership met for RPM’s annual Global EH&S Leadership Meeting over two days, exchanging best practices and new technologies in EHS management.

- 11 team leaders and supervisors on the Tremco CPG UK team earned their Institution of Occupational Safety and Health (IOSH) Managing Safely certification, which highlights their commitment to strengthening workplace safety, advancing risk management and ensuring compliance with industry standards.

- ~15,000 associates reached by our 12 Toolbox Talks, which cover topics such as EHS near misses, anti-harassment and discrimination, conflicts of interest and non-retaliation, among others.

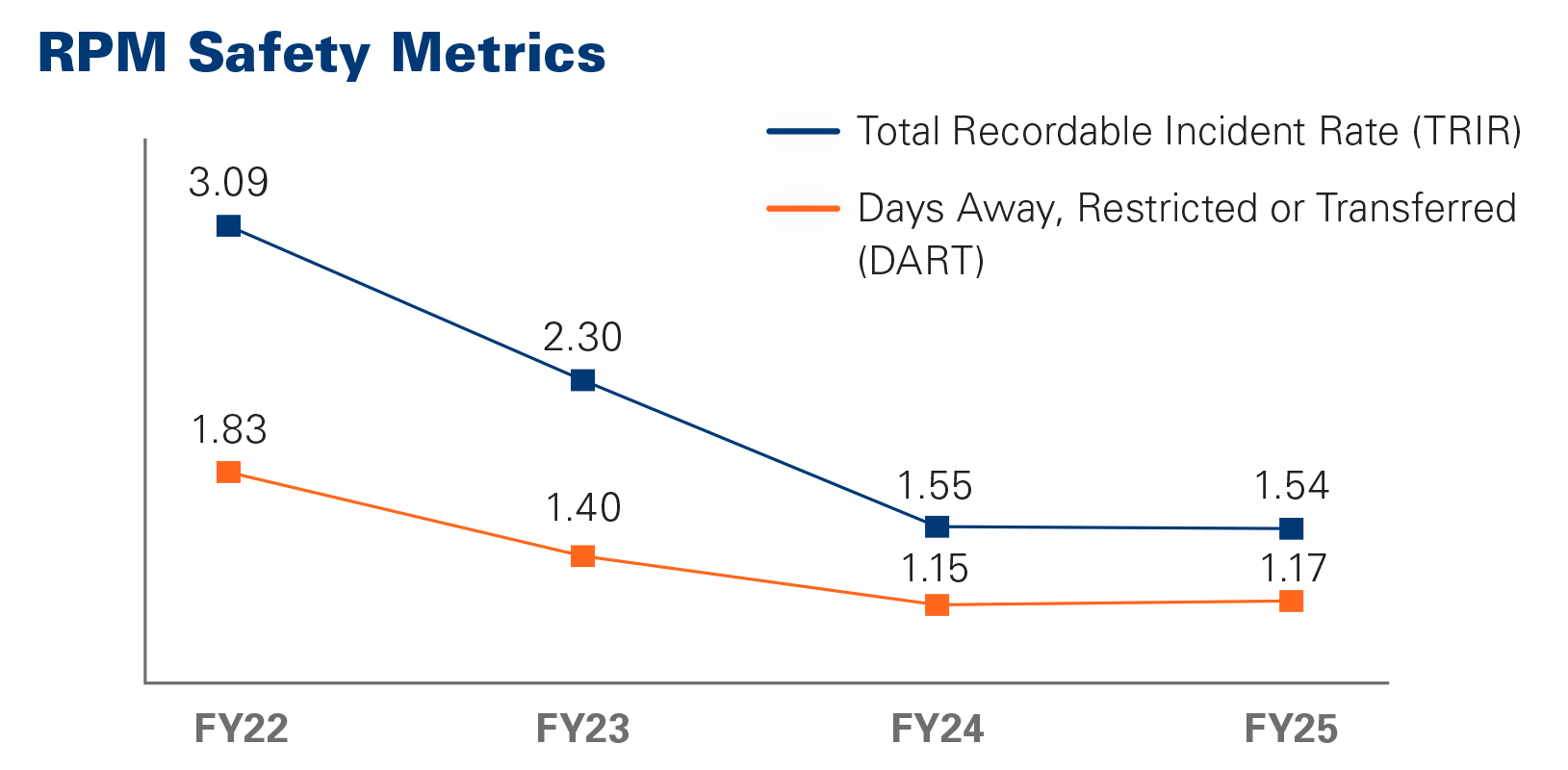

The total recordable incident rate (TRIR) and days away, restricted or transferred (DART) rate across RPM facilities has steadily declined since 2022.

HIGHLIGHT

In January 2024, RPM launched the PeopleWork Supervisor Safety Training program to improve and reinforce the safety leadership skill sets of frontline leaders in our manufacturing plants and in the field at project sites. The initial rollout included 39 U.S.-based supervisory associates at a Rust-Oleum plant, a Carboline plant and some members of Tremco’s Field Services group. The training consisted of eight weeks of virtual and interactive microtraining sessions that build upon learning and shared experiences.