As we work to fulfill our commitment to Building a Better World, our team is focused on top-performing products while maximizing material recyclability. Whether through partnerships with third-party recycling operations or the refurbishment and reuse of containers, we continually seek opportunities to make our packaging more environmentally friendly and keep recyclables out of landfills to reduce waste.

We use recycled content in packaging and look for ways to utilize less packaging in customer shipments. For example, Rust-Oleum uses 25% recycled content in most of its bottles for household, automotive and exterior cleaners. Additionally, they use nearly 6 million one-gallon paint cans each year that are made from 90% recycled material. In its shipping, Rust-Oleum’s corrugated boxes use an optimized blend of recycled and virgin wood pulp.

Stonhard uses 30% post-consumer recycled (PCR) content in its pails, and The Pink Stuff uses PCR in its bottles and recycled content in its paper packaging.

We also work with customers to ship orders together to reduce packaging waste, improve freight costs and increase customer convenience.

In FY25, RPM joined the Sustainable Packaging Coalition (SPC), a membership-based organization that believes in the power of industry to make packaging more sustainable through education, collaboration and action. It brings together businesses, educational institutions, organizations and government agencies that make up the entire life cycle of packaging.

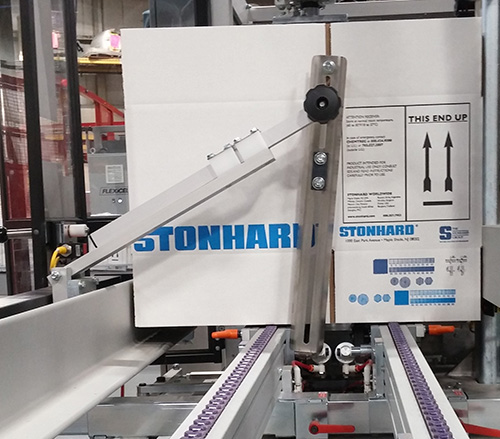

Rust-Oleum introduced an innovative, all-in-one packaging system for two-component kits, which ensures both components in the company’s flooring systems are shipped together. The system maximizes product delivery per pallet and enhances the efficiency of inventory handling, saving on shipping materials costs and emissions. Stonhard uses fill-and-seal packaging instead of rigid metal packaging in delivering its flooring, wall and lining solutions. This allows packaging material to be formed, filled with the product and sealed in one, continuous operation, enabling significantly less packaging waste.

RPM companies participate in the American Coatings Association’s (ACA) PaintCare Program to help their customers recycle paint easily and safely. We leverage the program’s more than 2,500 waste collection facilities across the United States. To date, the program has collected nearly 84 million gallons of post-consumer paint.